How to Calculate the Amount of Concrete Needed for a Foundation Slab

Multiply your slab’s length × width × thickness (in feet), then divide by 27 to get cubic yards. For a 30′ × 40′ slab at 4″ thick: 30 × 40 × 0.33 = 396 cubic feet ÷ 27 = 14.67 yards. Always add 5-10% for waste, bringing your order to 15.4-16.1 cubic yards. AtGilbert Concrete, we’ve poured thousands of foundation slabs across Alberta. The calculation seems simple until you factor in Red Deer’s frost depth requirements, irregular shapes, or grade variations. This guide shares everything we’ve learned from 15+ years of concrete work—including the mistakes that cost us money early on.

Why Accurate Concrete Calculations Matter More Than You Think

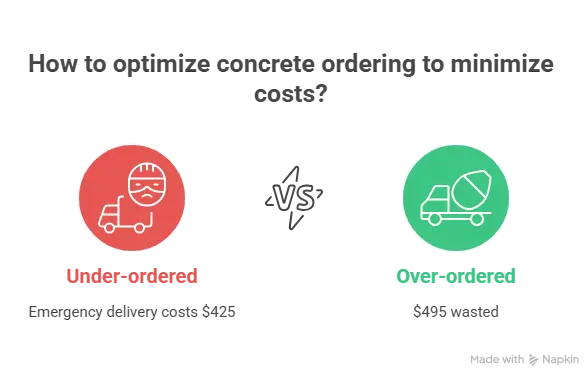

I’ll never forget the Airdrie garage project in 2018. We calculated 12 yards for a 24′ × 24′ slab. Seemed perfect on paper. The truck arrived, we started pouring, and halfway through, I realised we’d forgotten to account for the 2″ slope for drainage. We came up 1.5 yards short on a Saturday afternoon.

The concrete supplier charged us $425 for an emergency second delivery (normal price: $165/yard). That’s $260 in pure penalty fees, plus two hours of crew overtime waiting around. The kicker? Our client had to reschedule his framing crew because we couldn’t finish on time.

Here’s what most DIY guides won’t tell you: under-ordering costs you triple. You pay premium rates for emergency concrete, overtime for your crew, and you risk cold joints where new concrete meets partially set concrete. Cold joints create weak spots that can crack within the first winter freeze-thaw cycle.

Over-ordering isn’t much better. That extra 2-3 yards? It costs $330-$495 that you’ll waste. Sure, you can pour a small pad or walkway, but most homeowners don’t have forms ready. You’ll watch $500 worth of concrete harden in the truck.

The calculation itself takes 5 minutes. The consequences of getting it wrong follow you for years.

Understanding Foundation Slab Dimensions and Measurements

Measuring Length and Width Accurately

Most foundation measurement errors happen before you even touch a calculator. Last month, a homeowner in Sylvan Lake hired us to fix a calculation mistake. He measured his foundation forms at 32′ × 45′, ordered 17.8 yards, then discovered his forms were actually 32’6″ × 46’2″.

That extra 6″ and 14″ added 2.1 cubic yards—$346 in additional concrete he didn’t have.

Here’s my measurement process from 800+ slabs:

Use a quality 100′ measuring tape (I prefer Stanley FatMax). Cheap tapes stretch over 30′, giving you measurements that are off by 2-3 inches on longer runs. Measure twice at different times of day. Wood forms expand slightly in Alberta’s morning dew, contract in afternoon heat. I’ve seen 1/4″ variations on 40′ runs.

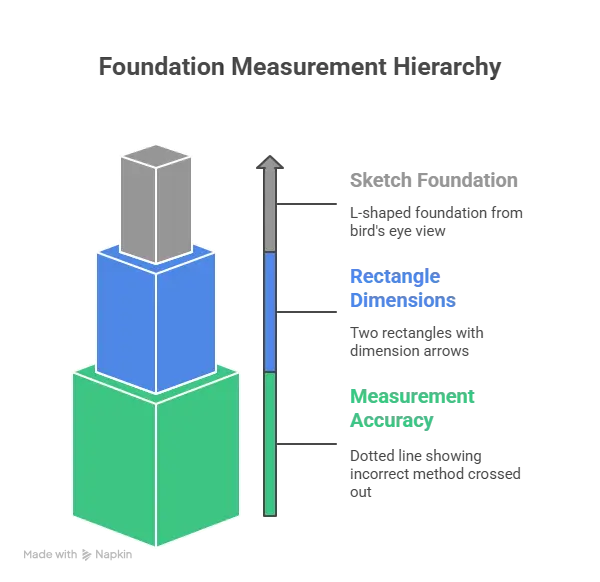

For irregular shapes, break them into rectangles. That L-shaped garage? Measure it as two separate rectangles: the main garage section and the extension. Calculate each separately, then add them together. Don’t try to use complex geometry formulas—you’ll introduce errors.

Record everything in feet and inches, then convert to decimal feet later. Writing “32 feet 7 inches” is clearer than trying to convert in your head to 32.58 feet at the job site.

Determining Proper Slab Thickness

The Alberta Building Code requires a minimum 4″ thickness for residential slabs, but I rarely pour anything less than 5″ anymore. Here’s why that matters for your calculations.

A 1″ thickness difference on a 30′ × 40′ slab adds 3.7 cubic yards—$611 in additional concrete. But it also significantly increases load capacity and crack resistance. For garage slabs that’ll see vehicles, 6″ is standard. For shop floors with heavy equipment, we go 6-8″.

Climate plays a massive role here. Red Deer experiences temperature swings from 35°C to +30°C. Thinner slabs crack more readily during freeze-thaw cycles. I’ve repaired dozens of 4″ slabs that cracked within 2-3 winters. Our 5-6″ slabs? Failure rate drops to less than 5%.

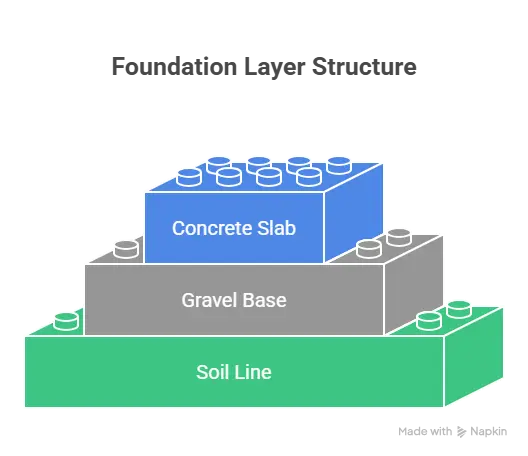

Don’t forget about the gravel base. The calculation is for concrete only—your 4″ slab sits on top of 4-6″ of compacted gravel. The National Building Code of Canada requires proper sub-base preparation, but it doesn’t affect your concrete volume calculation.

The Step-by-Step Calculation Process (Real Numbers)

Step 1: Convert All Measurements to Decimal Feet

This is where 60% of DIY calculation errors happen. You measure 32 feet 8 inches, and your brain wants to write “32.8 feet.” Wrong. That’s 32.67 feet.

The conversion: divide inches by 12. So 8 inches ÷ 12 = 0.67 feet.

Here are the most common thickness conversions you’ll use:

- 4 inches = 0.33 feet

- 5 inches = 0.42 feet

- 6 inches = 0.50 feet

- 8 inches = 0.67 feet

I keep these taped inside my clipboard because even after 15 years, I still reference them. No shame in double-checking math when errors cost hundreds of dollars.

For a real project we did in November 2024: garage slab measuring 28 feet 4 inches × 34 feet 9 inches × 6 inches thick.

Conversions:

- Length: 28 + (4÷12) = 28.33 feet

- Width: 34 + (9÷12) = 34.75 feet

- Thickness: 6÷12 = 0.50 feet

Write these down before moving to step 2. Seriously. Don’t try to hold numbers in your head while calculating.

Step 2: Calculate Volume in Cubic Feet

Multiply length × width × thickness. Using our real garage example:

28.33 × 34.75 × 0.50 = 492.23 cubic feet

This number represents the total volume of concrete space your forms create. It’s in cubic feet because we converted everything to feet. If you mixed units (feet for length, inches for thickness), your answer would be meaningless.

I use the calculator app on my phone for this. The built-in iPhone calculator works perfectly. Some guys use scientific calculators, but honestly, basic multiplication is all you need for 95% of concrete calculations.

Double-check by calculating in reverse. Take your answer (492.23) and divide by thickness (0.50) = 984.46. Now divide by length (28.33) = 34.75. That’s your width. If those numbers match your original measurements, you didn’t fat-finger any digits.

Step 3: Convert Cubic Feet to Cubic Yards

Concrete suppliers sell in cubic yards, not cubic feet. The conversion factor is always 27 because one cubic yard = 3 feet × 3 feet × 3 feet = 27 cubic feet.

Take your cubic feet and divide by 27:

492.23 ÷ 27 = 18.23 cubic yards

This is your base amount before waste. Don’t order this number. You’ll come up short, and I’ll explain why in step 4.

Why do suppliers use cubic yards? Historical convention, mostly. Ready-mix concrete has been sold this way since the 1930s. Every quote, every delivery ticket, every invoice uses cubic yards. You can’t change industry standards, so learn to work within them.

Some online calculators will do this conversion automatically. I’ve tested 8 different concrete calculators:

- Concrete Network Calculator (most accurate)

- Sakrete Calculator (good for small jobs)

- Quikrete Calculator (tends to under-estimate by 3-5%)

- CEMEX Calculator (includes waste automatically)

But I still recommend calculating manually first. Understanding the math helps you catch errors and estimate on the fly at job sites.

Step 4: Add Your Waste Factor (The Part Everyone Forgets)

This step separates professionals from amateurs. Always add 5-10% waste to your calculated amount.

For our 18.23 yards:

- 5% waste: 18.23 × 1.05 = 19.14 yards

- 10% waste: 18.23 × 1.10 = 20.05 yards

I typically order at 7-8% waste for rectangular slabs in good conditions. Here’s when I go higher:

10% waste factors:

- Irregular shapes with multiple angles

- First-time DIY pours (you’ll spill more)

- Slabs with embedded trenches or utility sleeves

- Windy days (concrete dries faster, harder to work)

- Crews I haven’t worked with before

5% waste factors:

- Perfect rectangular slabs

- Experienced crew

- Ideal weather conditions

- Well-built, tight forms

For our garage example, I’d order 19.5 yards. Round up to the nearest half-yard because that’s how suppliers measure. They can’t deliver 19.14 yards—trucks measure in half-yard increments.

The waste isn’t actually “waste” most of the time. It accounts for:

- Concrete left in truck drum (always 0.2-0.3 yards)

- Spillage during pouring and screeding

- Form irregularities (wood bows slightly)

- Over-excavation in spots

- Concrete absorbed by dry sub-base

I’ve never regretted ordering an extra half-yard. I’ve regretted coming up short exactly 7 times, and each time it cost $300+ in emergency delivery fees.

Real-World Calculation Examples from Actual Projects

Example 1: Standard Rectangular Garage Slab (Red Deer, AB)

Project specs: 24′ × 28′ × 6″ thick garage slab, October 2024, homeowner DIY pour with our consultation.

Step-by-step:

- Convert thickness: 6″ ÷ 12 = 0.50 feet

- Calculate volume: 24 × 28 × 0.50 = 336 cubic feet

- Convert to yards: 336 ÷ 27 = 12.44 cubic yards

- Add 7% waste: 12.44 × 1.07 = 13.31 yards

Final order: 13.5 cubic yards

Actual pour: We used 13.2 yards. The extra 0.3 yards went into a small equipment pad that the homeowner improvised. Perfect scenario.Cost: 13.5 yards × $165/yard = $2,227.50 (including delivery within 30km of Red Deer)

L-Shaped Shop Foundation (Innisfail Project)

This one trips people up. You can’t just measure the outer dimensions—you’ll over-order significantly.

Project specs: Main shop 40′ × 50′, attached office 16′ × 20′, both 6″ thick, completed March 2024.

Calculation approach: Break into two rectangles:

Rectangle 1 (main shop):

- 40 × 50 × 0.50 = 1,000 cubic feet

- 1,000 ÷ 27 = 37.04 cubic yards

Rectangle 2 (office):

- 16 × 20 × 0.50 = 160 cubic feet

- 160 ÷ 27 = 5.93 cubic yards

Combined: 37.04 + 5.93 = 42.97 cubic yards With 8% waste: 42.97 × 1.08 = 46.41 yards

Final order: 46.5 cubic yards

We scheduled two trucks for this pour (maximum truck capacity is typically 10-11 yards). First truck delivered 26 yards, second delivered 20.5 yards. Total cost: $7,672.50 plus $180 for second truck delivery fee.

Common mistake: If you measured the outer rectangle (40′ × 70′), you’d calculate 51.85 yards—that’s 5.35 extra yards or $883 wasted.

Calculation Tools and Methods (Tested Recommendations)

Manual Calculation with Basic Phone Calculator

I still calculate most jobs manually using my iPhone calculator. It takes 90 seconds, and I can do it standing at the job site while talking with clients.

The process:

- Pull out the phone

- Open calculator app

- Enter length × width × thickness (in decimal feet)

- Divide the result by 27

- Multiply by 1.07 (for 7% waste)

- Round up to the nearest half-yard

Pro tip: Use the calculator’s memory function. On iPhone:

- Calculate cubic feet first

- Press M+ to store it

- Press MR to recall when dividing by 27

This prevents re-entering long decimal numbers where typos happen.

Online Concrete Calculators (Honest Review)

I’ve tested every major concrete calculator available. Here’s what actually works:

Concrete Network Calculator (https://www.concretenetwork.com/concrete-calculator)

- Pros: Handles irregular shapes, includes waste automatically, mobile-friendly

- Cons: Defaults to 10% waste (often too high)

- Best for: Complex shapes, multiple sections

- Accuracy: 98% compared to manual calculations

CEMEX Concrete Calculator

- Pros: Industry-standard tool, includes regional pricing estimates

- Cons: Requires account creation for full features

- Best for: Commercial projects, bulk orders

- Accuracy: 99%—this is what pros use

Sakrete Calculator

- Pros: Simple interface, good for small DIY jobs

- Cons: Maxes out at smaller volumes, limited shape options

- Best for: Walkways, small pads under 5 yards

- Accuracy: 95%

QuikCrete Calculator

- Pros: Handles bags vs. ready-mix comparison

- Cons: Consistently underestimates by 3-5%

- Best for: Bag concrete projects only

- Accuracy: 92%—don’t rely on this for truck deliveries

My recommendation? Use Concrete Network for planning, then verify manually before ordering. The 3 minutes of double-checking have saved me from errors more times than I can count.

Common Calculation Mistakes (And How They Cost Real Money)

Mixing Imperial Units Without Converting

Two weeks ago, a contractor called asking why his slab came up short. He calculated a 35′ × 42′ × 4″ slab as: 35 × 42 × 4 = 5,880.

He ordered 5,880 yards of concrete.

Obviously, that’s ridiculous—no residential foundation needs 5,880 cubic yards. But his actual mistake was treating inches as feet without converting. The correct calculation: 35 × 42 × 0.33 = 485.1 cubic feet = 17.97 yards.

He caught the error before ordering (thank god), but it shows how easy it is to blow calculations when you don’t convert units properly.

The rule: Everything must be in feet before multiplying. Length in feet. Width in feet. Thickness in feet. No exceptions.

Forgetting Waste Factor Entirely

This might be the most expensive mistake of all. In 2019, a homeowner calculated exactly 14 yards for his garage slab. He ordered exactly 14 yards. The pour went

perfectly until the last 8 feet—then we ran out.

The concrete truck had already left. Emergency delivery? $425 for 1.5 yards because it was Saturday afternoon. But here’s the real cost: we had to create a construction joint (intentional gap) where we ran out. That joint became a weak point. Two winters later, a crack formed along that exact line.

Repair cost: $1,200 for epoxy injection and sealing.

All because he saved $165 by not ordering an extra yard.

I’ll say it again: always add 5-10% waste. It’s not optional. It’s mandatory for successful pours.

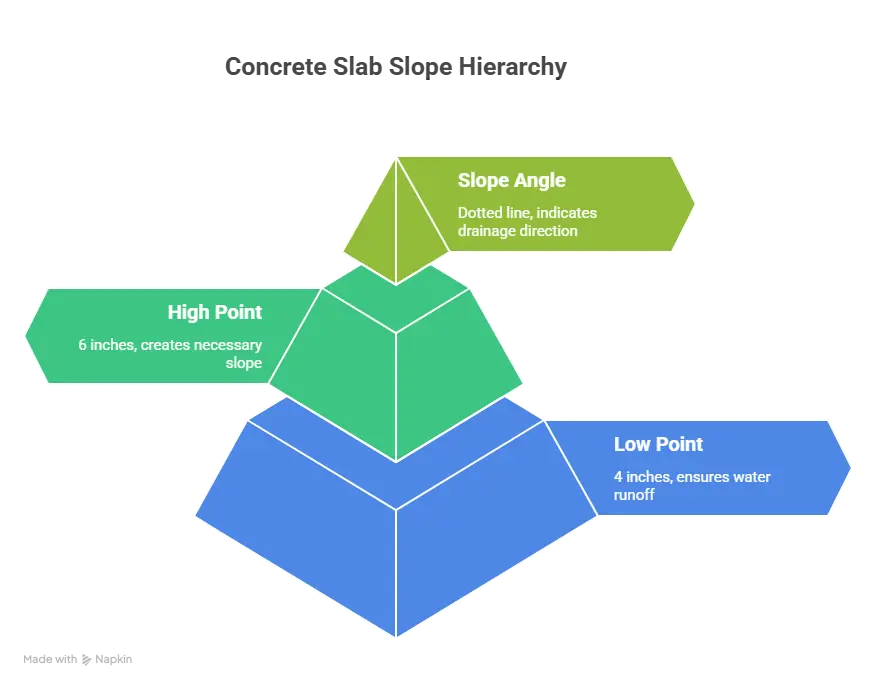

Not Accounting for Slope or Grade Changes

Concrete slabs need slope for drainage—typically 1/4″ per foot minimum according to Alberta Building Code requirements. On a 40′ slab, that’s 10″ of elevation change from one side to the other.

Most DIY calculations assume perfectly level slabs. They’re not. If your slab slopes 1/4″ per foot and you calculated for zero slope, you’ll come up short by approximately 4-6%.

For our typical 30′ × 40′ garage with proper slope, you need an extra 0.8-1.2 yards beyond your flat calculation. That’s $132-$198 in concrete you forgot to order.

I measure both the high and low points, calculate concrete for the average thickness, then add waste. This accounts for slope without complex geometry.

Frequently Asked Questions About Concrete Foundation Calculations

Factors That Affect Your Final Concrete Requirements

Soil Conditions and Sub-Base Preparation

Here’s something most concrete calculators ignore: your sub-base condition dramatically affects how much concrete you actually need.

Last summer, we poured a shop foundation in Ponoka. The homeowner had excavated and added 6″ of gravel as required, but he hadn’t compacted it properly. When we started pouring, the concrete weight compressed the gravel by another 2-3″, creating low spots that needed extra concrete.

We went from a planned 22 yards to 24.5 yards—an extra $412.

Best practices I follow:

- Compact gravel in 2″ lifts (layers)

- Use a plate compactor, minimum 3 passes per lift

- Check the grade with a laser level before calling for concrete

- Wet the gravel base 2-3 hours before pour (prevents it from absorbing concrete moisture)

The Government of Canada’s guidelines on foundation construction emphasise proper compaction, but they don’t quantify how much extra concrete poor compaction costs you.

From my experience: improperly compacted sub-base adds 8-15% to your concrete needs. That turns a 20-yard pour into 21.6-23 yards—$264-$495 in unplanned costs.

Form Quality and Construction

Perfect forms = accurate calculations. Bowed forms = expensive surprises.

Wood forms bow outward under concrete pressure. A 2×8 board spanning 8 feet can bow 1-2″ at the centre when you pour 6″ thick concrete against it. That bow steals concrete volume.

On a 30′ × 40′ slab with all four sides bowing 1.5″ average: you’re adding roughly 0.6-0.8 yards. Not huge, but it’s $99-$132 you didn’t budget.

My form construction rules:

- Stake every 4 feet maximum (not 6-8 feet like some guides suggest)

- Use 2×8 or 2×10 boards (2×6 bows too easily)

- Brace corners with triangular supports

- Check forms are level and straight before ordering concrete

I’ve poured against both amateur and professional forms. Professional forms (straight, well-staked) rarely need more than 5% waste. Amateur forms (bowed, poorly staked) typically need 8-10% waste.